Top 10 Common Appliance Issues & Possible Repairs

10 Common Washer Problems We Fix Every Day

Having trouble with your washing machine? Here are the most common issues our technicians handle during a Washer Repair Service.

- 1Clothes not getting cleaned properly

Often caused by incorrect cycle or temperature settings, an overloaded drum, a partially blocked filter, or using too little (or the wrong type of) detergent.

- 2Washer leaking water

Common sources include worn door boot (front-loaders), loose or cracked hoses, a faulty drain pump, or a damaged tub seal.

- 3Loud banging or grinding noises

Can indicate worn drum bearings, a failing motor, loose components, or an unbalanced load hitting the cabinet during spin.

- 4Washer stops mid-cycle

May be related to a faulty door/lid switch, control board issues, drain problems, or power interruptions to the machine.

- 5Clothes come out soaking wet

Usually a spin issue: failing motor, worn belt, blocked drain pump, or an unbalanced load preventing full spin speed.

- 6Excessive vibration or “walking” washer

Often caused by worn shock absorbers or suspension rods, damaged motor mounts, or the washer not being level on the floor.

- 7Washer won’t start

Check power and breakers first. If power is good, the issue may be with the door lock, control board, user interface, or an internal fuse.

- 8Washer overfilling or overflowing

Can be due to a clogged pressure hose, faulty water level sensor, stuck water inlet valve, or control board not shutting the valve off.

- 9Clothes not rinsing or draining properly

A partially blocked drain pump, kinked/clogged drain hose, or too much detergent can leave clothes soapy and damp.

- 10Washer won’t agitate

Can point to a worn drive belt, failed motor, stripped agitator dogs (top-loaders), or transmission/gearcase problems.

If you’re seeing any of these issues, it’s usually cheaper to repair early before damage spreads to other parts.

Book Your Washer Repair with Advance Appliance Ltd

10 Common Dryer Problems We Fix Daily

Here are the most frequent issues our certified technicians repair during a Dryer Repair Service.

- 1Poor or No Airflow

Lint buildup in the vent, clogged lint trap, or crushed ducts reduce airflow and cause long drying times.

- 2Dryer Not Heating

Often caused by a failed heating element, thermostat, cut-off fuse, or improper voltage supply.

- 3No Power at All

Can be due to a tripped breaker, blown thermal fuse, faulty outlet, or internal electrical failure.

- 4Dryer Won’t Start

Door switch issues, broken start switch, user interface failure, or control board malfunction.

- 5Drum Not Turning

Usually a worn or broken belt, seized rollers, faulty motor, or damaged idler pulley.

- 6Dryer Overheating

Caused by blocked vents, defective cycling thermostat, or stuck heating element relay.

- 7Loud Noise or Vibration

Worn drum rollers, blower wheel issues, loose panels, or misaligned leveling legs.

- 8Clothes Not Drying

Vent blockage, clogged lint filter, weak heating, or a faulty moisture sensor prevents proper drying.

- 9Burning or Musty Smells

Lint near the heater, worn belt rubbing, or buildup on the heating element can cause smells.

- 10Dryer Won’t Stop Running

Faulty cycling thermostat, defective timer, stuck relay, or moisture sensor failure.

10 Common Cooktop Problems We Repair

Gas, electric, or induction – here are the most common issues we see during a Cooktop Repair Service.

- 1Burner Not Heating Properly

Blocked burner ports, dirty electrodes, faulty igniters or elements can all cause weak or inconsistent heat.

- 2One or More Burners Won’t Light

Common causes include bad ignition switches, loose wiring, failed spark modules, or faulty flame sensors.

- 3Uneven Heat Distribution

Off-center burner caps, partially blocked ports, or damaged elements can create hot and cold spots in your pan.

- 4Flame Too High or Too Low

Incorrect air–gas mix, misadjusted air shutters, or gas pressure issues can cause unstable or unsafe flames.

- 5Power On but No Heat

For electric or induction units, failed elements, surface boards, or sensors may stop burners from heating.

- 6No Power at All

Tripped breakers, loose connections, damaged power cords, or internal control failures can shut the cooktop down.

- 7Burners Won’t Stay Lit

Weak or dirty flame sensors, faulty thermocouples, or poor gas flow can cause burners to shut off shortly after ignition.

- 8Excessive Smoke While Cooking

Spills, grease buildup, or blocked ports can cause smoke and odours – especially on gas burners.

- 9Not Reaching Set Temperature

Faulty temperature sensors, failing elements, or incorrect calibration can stop the cooktop from delivering full heat.

- 10Unpleasant or Gas Odours

Spills, grease, or (on gas models) possible leaks or incomplete combustion—these should be inspected promptly for safety.

If you smell gas, see unstable flames, or breakers keep tripping, stop using the cooktop and book service.

Book Your Cooktop Repair Today

10 Common Dishwasher Problems We Repair

Here are the top issues our certified technicians fix during a Dishwasher Repair Service.

- 1Faulty Door Latch

A weak, damaged, or misaligned latch prevents the dishwasher from starting or sealing properly.

- 2Leaking Water

Loose door seals, cracked hoses, damaged sump assembly, or failing water inlet valves are common leak causes.

- 3Noisy Operation

Grinding, humming, or buzzing may indicate circulation pump wear, debris in impellers, or failing wash motors.

- 4Not Cleaning Dishes

Blocked spray arms, dirty filters, weak water pressure, or faulty wash motors reduce cleaning performance.

- 5Not Draining Properly

Clogged drain hoses, blocked filters, jammed drain pumps, or check valve issues can leave water at the bottom.

- 6Unpleasant Odors

Food debris, grease buildup, or slow drainage can cause odors—cleaning and proper maintenance resolve this.

- 7Not Filling with Water

Faulty inlet valves, clogged screens, low water pressure, or float switch issues prevent proper filling.

- 8Poor Drying

A failing heating element, faulty thermostat, or broken vent fan can lead to wet or cloudy dishes.

- 9Maintenance-Related Failures

Worn seals, dirty filters, loose hoses, and unmaintained spray arms can cause performance problems over time.

- 10Detergent Buildup or Oversudsing

Using too much detergent, or the wrong type, can clog the system and create excessive suds.

10 Common Microwave Problems We Repair

These are the most frequent issues our technicians solve during a Microwave Repair Service.

- 1Faulty Door Switch

A broken or misaligned door switch stops the microwave from running for safety and usually needs replacement.

- 2Blown Fuses or Tripped Breakers

Power surges or internal shorts can blow fuses or trip breakers, leaving the microwave completely dead.

- 3Poor Power Supply

A weak outlet, loose plug, or unstable voltage can cause flickering displays, random shutoffs, or no operation.

- 4Failed Magnetron

If the magnetron fails, the unit may run but food will not heat properly.

- 5Incorrect Timer or Control Settings

A faulty touchpad or control board can cause wrong run times, random stopping, or unresponsive buttons.

- 6Excessive Arcing or Sparking

Food splatter, metal objects, or damaged waveguide/cover can cause arcing—cleaning and inspection are important.

- 7Faulty Temperature / Safety Controls

Defective thermostats or sensors may shut the unit down too soon or allow internal overheating.

- 8Broken Interior Light

Burned-out bulbs or wiring faults require safe disassembly and correct replacement.

- 9Electromagnetic Interference

Nearby devices or poor grounding can interfere with controls, displays, or Wi-Fi enabled models.

- 10Poor Ventilation / Overheating

Blocked vents, tight cabinets, or grease buildup cause overheating and shorten component life.

10 Common Stove Problems We Repair

Here are the issues our certified technicians most often fix during a Stove Repair Service.

- 1Faulty Igniter

When the igniter is weak or dead, burners fail to light or take too long to ignite—replacement resolves the issue.

- 2Clogged Burner Orifice

Grease, debris, or food spills block gas flow; cleaning the orifice restores even flame performance.

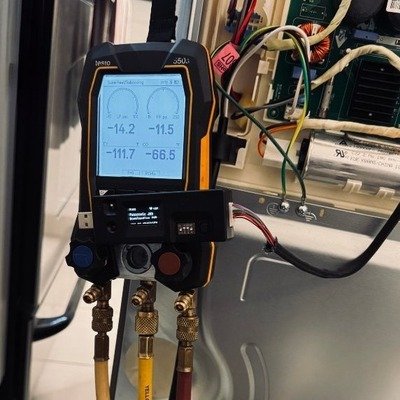

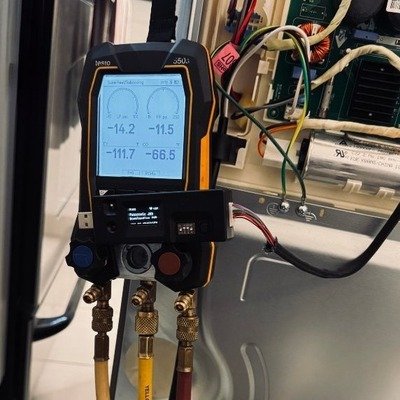

- 3Poor Gas Flow

Gas supply issues, regulator failure, or valve restrictions require a trained gas-licensed technician.

- 4Broken Heating Element

Electric ranges may stop heating due to cracked or burnt-out elements—replacement restores performance.

- 5Defective Thermostat

A faulty thermostat causes inaccurate temperatures, uneven cooking, or overheating issues.

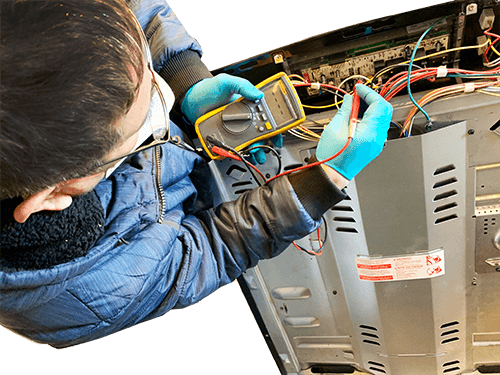

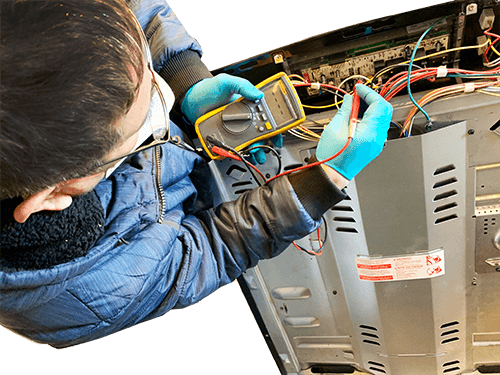

- 6Loose or Broken Wiring

Electrical faults can prevent burners or the oven from heating and should be handled by professionals only.

- 7Grease & Debris Buildup

Heavy grease inside the oven cavity affects temperature accuracy and can create smoke or fire hazards.

- 8Worn or Damaged Door Gasket

A weak seal lets heat escape, leading to long cook times and uneven baking—replacement is recommended.

- 9Faulty Temperature Control Knobs

Broken or inaccurate dials affect burner output; internal valve or switch replacement may be needed.

- 10Control Board or Display Failure

Error codes, dead displays, or unresponsive buttons often point to a failing control board—diagnosis is required before ordering parts.

10 Common Oven Problems We Repair

From gas safety issues to temperature problems, here are the most common faults we see during an Oven Repair Service.

- 1Dirty or Neglected Oven Interior

Heavy grease and carbon buildup can affect performance and create smoke. Technicians focus on repair; for heavy cleaning, follow the manufacturer’s instructions or use a professional cleaning service.

- 2Door Not Sealing Properly

A misaligned door, worn hinges, or damaged gasket lets heat escape, causing long cook times and uneven baking.

- 3Gas Smell or Suspected Leak (Gas Ovens)

If you smell gas, shut the oven off, ventilate the area, and contact a gas-licensed professional immediately—do not attempt DIY repairs.

- 4Failed Heating Elements

Bake or broil elements that are cracked, blistered, or open-circuit will prevent the oven from heating or browning correctly.

- 5Preheating & Temperature Problems

Faulty sensors, damaged elements, or miscalibrated thermostats cause slow preheat, temperature swings, and inconsistent baking results.

- 6Clock & Timer Malfunctions

Broken clocks, timers, or control panels can affect delayed start, timed baking, and shutoff functions.

- 7Damaged or Loose Wiring

Burned connectors or loose wires can cause intermittent heating or complete power failure and should be handled by a professional.

- 8Igniter, Valves & Switch Issues (Ranges)

Weak igniters, stuck gas valves, or faulty switches can prevent the oven from lighting or maintaining flame in gas ranges.

- 9Broiler Not Working Properly

Faulty broil elements, gas valves, or control faults lead to poor browning or no broil function at all.

- 10Worn Racks & Interior Hardware

Warped racks, worn supports, or damaged guides can make it difficult to position pans safely and evenly inside the oven.

10 Common Refrigerator Problems We Repair

These are the most frequent issues our technicians diagnose during a Refrigerator Repair Service.

- 1Dirty Condenser Coils

Dusty or greasy coils cause overheating and poor cooling—cleaning every 6–12 months improves efficiency.

- 2Blocked Air Vents

Food packages or ice buildup blocking vents disrupt airflow and lead to warm fridge temperatures.

- 3Incorrect Thermostat Settings

Misadjusted or faulty thermostats can cause freezing, warming, or inconsistent cooling.

- 4Overloaded Freezer

Overpacked freezers restrict airflow and cause both freezer and refrigerator sections to warm up.

- 5Worn Door Seals / Gaskets

Cracked, loose, or warped gaskets allow cold air to escape, forcing the fridge to work harder and cool poorly.

- 6Blocked Defrost Drain

Frozen or clogged drains cause water leaks, ice sheets, and restricted airflow inside the refrigerator.

- 7Failing Evaporator or Condenser Fan

Weak or dead fans prevent proper air circulation, causing warm spots and inconsistent cooling.

- 8Motor or Compressor Problems

A weak motor or failing compressor leads to long run times, poor cooling, or complete no-cool situations.

- 9Ice Build-Up

Excess frost blocks airflow and reduces cooling performance—often caused by sensor, heater, or drain issues.

- 10Compressor Failure

A failing compressor prevents the fridge from cooling at all—requires professional diagnosis before replacement.

10 Common Range Hood Problems We Repair

These are the most frequent issues we diagnose during a Range Hood Repair Service.

- 1Clogged Grease Filters

Dirty filters reduce airflow and cause strong cooking odors—cleaning or replacing restores performance.

- 2Weak or Slow Fan

Obstructions, failing motors, or loose connections can prevent the blower from reaching full speed.

- 3Blocked Exhaust Vent

Indoor or outdoor vent blockages restrict airflow, causing smoke buildup and poor ventilation.

- 4Lights Not Working

Burned bulbs, faulty wiring, or damaged sockets can lead to lighting failure under the hood.

- 5Loud or Vibrating Motor

Unbalanced blowers, worn bearings, or loose screws often cause grinding, humming, or rattling sounds.

- 6Grease Build-Up on Surrounding Walls

Poor ventilation or clogged filters cause excess grease to escape—clean surfaces and restore airflow.

- 7Loose or Improper Duct Connections

Poorly sealed ducts leak air, reduce suction, and create excess noise—tightening and sealing resolves it.

- 8Motor Running but Fan Not Spinning

Obstructions, slipping fan wheels, or a damaged blower assembly can prevent blade rotation.

- 9Loose Screws or Internal Components

Vibrations can loosen internal hardware—tightening ensures safe, quiet operation.

- 10Vent Cover Not Opening or Closing

Broken hinges, stuck dampers, or poor lubrication prevent proper airflow control—repairs restore full function.

10 Common Ice Maker Problems We Repair

Our Appliance Repair team regularly diagnoses and fixes these issues during an Ice Maker Repair Service.

- 1Poor Water Flow or Low Pressure

Weak water supply, restricted valves, or faulty filter heads reduce fill levels and slow ice production.

- 2Clogged Water Line

Mineral deposits, debris, or old filters can partially block the line—filters should typically be replaced every 6 months.

- 3Overfilled or Underfilled Ice Molds

Incorrect fill levels may be due to faulty water valve control or internal adjustments—best verified by a technician before parts are replaced.

- 4Freezer Temperature Too Warm or Too Cold

Incorrect settings, bad sensors, or sealed system issues affect cube size and production speed and should be professionally checked.

- 5Shutoff Arm or Sensor Not Working

A stuck arm or faulty level sensor may not stop production, causing jams or overflowing bins.

- 6Ice Maker Motor or Drive Issues

Worn gears, broken couplers, or failed motors prevent the ejector from turning—diagnosis by a technician is recommended before parts replacement.

- 7Leaks from Valves, Hoses, or Seals

Drips behind or under the fridge may come from loose fittings, cracked lines, or faulty valves and should be professionally inspected.

- 8Clogged or Frozen Drainage

Blocked drains can cause water to pool around the ice maker area or freeze into sheets—underlying causes should be confirmed before repairs.

- 9Excess Frost or Ice Buildup

Insufficient defrost, warm air leaks, or airflow issues can cause heavy frost, affecting both ice quality and production.

- 10Control Board or Sensor Failures

Faulty boards or sensors can cause random stops, no production, or incorrect temperatures—these should be tested by a professional before ordering parts.

The information provided on the Advance Appliance Ltd. website is for general informational purposes only and should not be considered technical or professional repair advice. We strongly recommend contacting a licensed appliance repair technician for accurate diagnosis and repair.

While every effort is made to keep our troubleshooting guides and repair information accurate and up to date, we cannot guarantee that all details are complete, error-free, or suitable for DIY use. Appliance systems vary by brand, model, and condition, and improper handling can cause damage or safety hazards.

Advance Appliance Ltd. is not responsible for any injuries, damages, or losses that may occur as a result of using information from this website. This disclaimer applies only to the content on our website and does not extend to external repair resources or third-party sites.

Thank you for using our website and for choosing Advance Appliance Ltd. for your appliance repair needs.