Testing Oven Temperature

Preperation for Professional Technicians

Tools Required:

- Digital Multimeter with temperature measurement functions.

- Thermocouple that is compatible with the multimeter, sample: Type-K thermocouple with standard shrouded banana jack.

Steps for Testing Oven Temperature

1. Place 1 rack at the center of the oven, and put your thermocouple at the center of the rack making sure the thermocouple is not touching any of the metal part of the rack.

- 2. Preheat The Oven to 350 °F , Note: DO NOT OPEN THE DOOR until the procedure of gathering data is complete.

- 3. After preheat is finished write down the first CUT IN temperature and the first CUT OUT temperature.

- After 20 minutes start recording the temperatures. As the oven begins to cool down the thermostat or electronic cntrol will turn the burner or heating element back on to raise the temperature.

- 4. Usually at a setting of 350 °F this will be around 330 °F & 370 °F but could be higher or lower. • DO NOT OPEN THE DOOR.

- 5. Wait until the oven cools down and the control turns the element or burner back on. Write down the CUT IN and CUT OUT temperatures again.

- 6. Repeat these steps until you have recorded five CUT IN and five CUT OUT temperatures.

- 7. Add the CUT IN & CUT OUT temperature

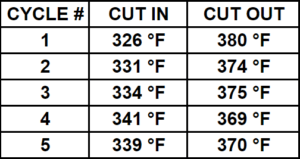

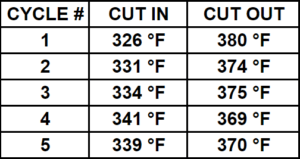

- 8. See Fig. 1 Sample data

- 9. Add these numbers all together and then divide by 10 to get the overall AVERAGE of your oven temperature.

- 10. TOTAL = 3539 divided by 10 = 353.9 °F average temperature

Sample Data: Fig.1

General Information:

- The point at which the element comes on is called the CUT IN temperature.

- The point at which the element goes off is called the CUT OUT temperature.

- In electric ovens it is very common for the temperature to continue to rise even after the element has turned off.

- On most ranges there will be an indicator light of some type to signal when the element comes on or goes off.

Oven Calibration

Most newer oven equipped with electronic control unit can be calibrated. Alway refer to the appliance manual ( calibrate the oven if only necessary or needed )

General Procedure: Oven Temperature Calibration

This steps is only a sample, and cannot be used as guide for other brands of appliance. This sample steps of calibration taken from a whirlpool brand appliances oven. Always refer to you use and care manual for setting up oven calibration.

Temperature Calibration : Whirlpool Model: WOS51EC7AS

1. Plug in oven or connect power.

2. Press SETTINGS until “TEMP CALIB” is displayed.

3. Press START. The current offset, if any, is displayed in a

temperature range from -30°F (-18°C) to 30°F (18°C).

4. Press the “1” keypad to increase the temperature in

5°F (3°C) increments.

5. Press the “2” keypad to decrease the temperature in

5°F (3°C) increments.

6. Press START to activate the desired temperature.

NOTE: If START is not pressed within 1 minute, the

adjustment will be ignored.

Common Complaint

Common Issues or Complaint:

Oven temperature is fluctuating and not stable.

Below are list of possible reasons for not stable oven temperature

- User had canceled the initial settings and set the oven again to a lower or higher temperature. The displayed temperature within the oven control will likely not be the same from which it was initially seen prior to changing the settings. This is normal as the oven fluctuates CUTS IN and CUT OUT. The oven does not show the fluctuation; it has a built-in logic that averages all the data gathered during operation .. By canceling or changing settings of the oven control. It will likely reset or data will be erased and will need a few minutes for the control to get the accurate thermocouple reading.

- Out of range or defective oven sensor ( oven sensors are not common parts to fail but still this component can fail sometimes, so no exemption to skip checking this component. Its resistance value must align with oven sensor chart vs the ambient temperature inside the oven).

- Thermal fuse failed ( if the oven exceeds safe operating temperature , Thermal fuse will open and for most thermal fuse it is non-resettable,Thermal fuse is used as a safety component and it cannot be bypassed permanently cause its purpose is to prevent unsafe operation and possibly cause more damage to the unit. If this is the condition that thermal fuse failed ( Components needed to be inspected or tested are cooling fan, oven sensor, shorted relay in control board.

- Faulty oven relay control board ( relay maybe shorted or partially closing contacts ).

- Faulty oven elements ( make sure to check if all elements are within its resistance value and should not be shorted to ground ).

Disclaimer

The information provided on the Advance Appliance Ltd. website is for informational purposes only and is not intended as professional advice. We strongly recommend that you consult a professional appliance repair person for all your appliance repair needs. Additionally, while every effort has been made to provide accurate and up-to-date information, we cannot guarantee that the information provided is complete or free of errors. Therefore, Advance Appliance Ltd. disclaims any and all liability for damages resulting from use of the information on our website. Please be aware that this disclaimer applies only to the information contained on our website and not to any other appliance repair information sources. Thank you for your understanding.