Model and Serial - Correct Part Request

Why is it that the model number and serial number of the appliance or appliances important?

The explanations are as follows.

The manufacturer will need this information when you are claiming a warranty of your appliance. Some appliances may be covered with limited warranty up to 10 years. Check your entitlement when claiming warranty of your appliance.

You could also check the Model number and Serial number for any reworks or recall issued by the manufacturer. Most of the time the manufacturer will communicate with the owner of the appliance or appliances if it has been affected by any type of rework or recalls. Make sure to register your appliance after purchasing.

The Model number and Serial number TAG sometimes comes with extra added information. Ex. Year it was manufactured, current consumption, type of gas used with the refrigerator, the manufacturers contact support information and many more.

If your appliance does not have or has missing with Model # & Serial # TAG Sticker, when something goes wrong with your appliance which now requires service. The manufacturer may refuse to service your appliance, the warranty will be void, The technician also cant verify the version and it may be difficult to get parts lookup although sometimes the part number can be obtain with the part # itself or by comparing the actual parts. Make sure not to remove the Identification Sticker of your appliance or appliances.

Understanding - Model Number & Serial Number

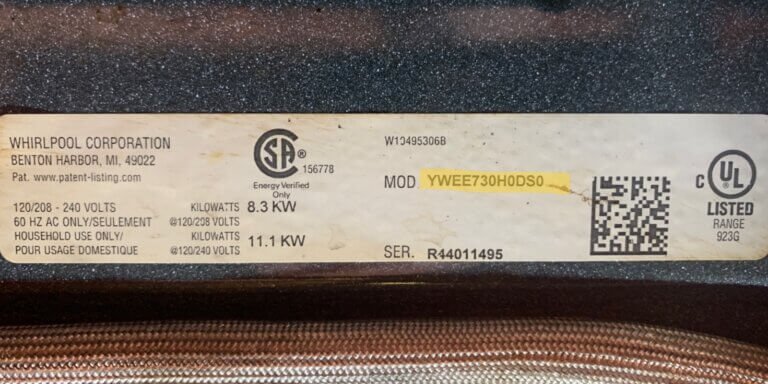

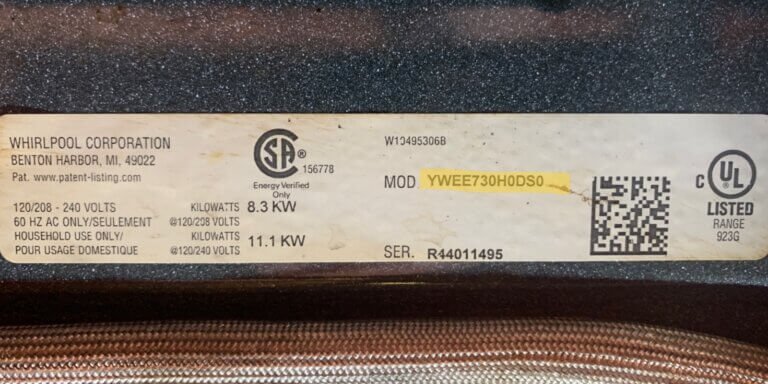

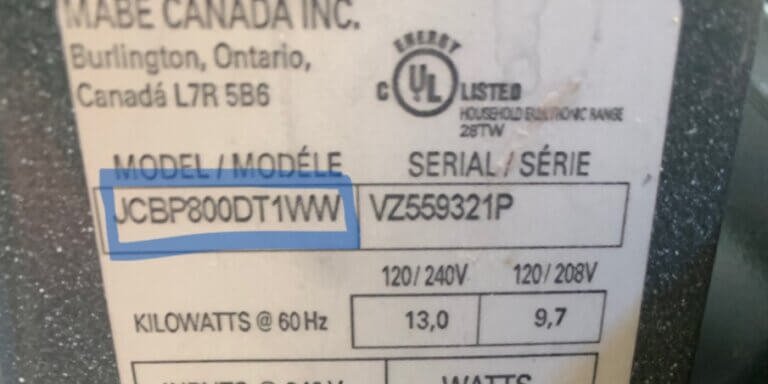

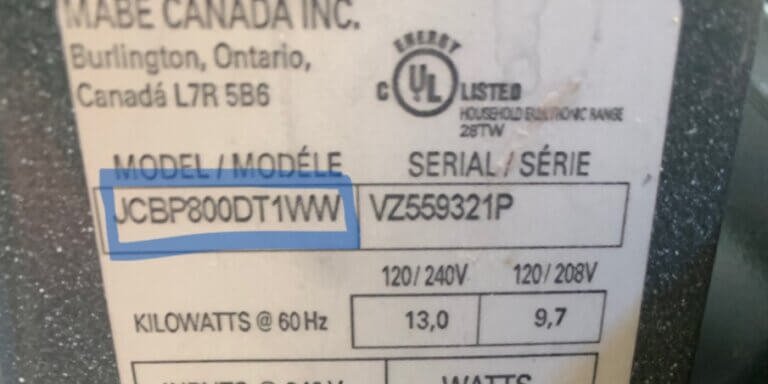

Sample 1

MODEL NUMBER: YWEE730H0DS0

This model has few versions and it looks like the differences are just cosmetics. Colors: White, Black, Stainless

Cosmetic appearances are very important especially with the customers point of view. If a technician is trying to replace a control panel, or any parts that have to do with cosmetic appearance. The technician or customer has to make sure to obtain the complete model number and serial number. Failure to do this will result in receiving or ordering incorrect parts. There are also reasons that the part may not be compatible with the appliance being serviced or repaired.

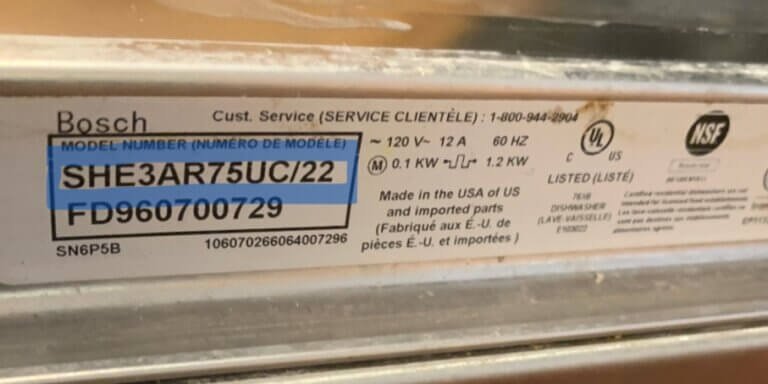

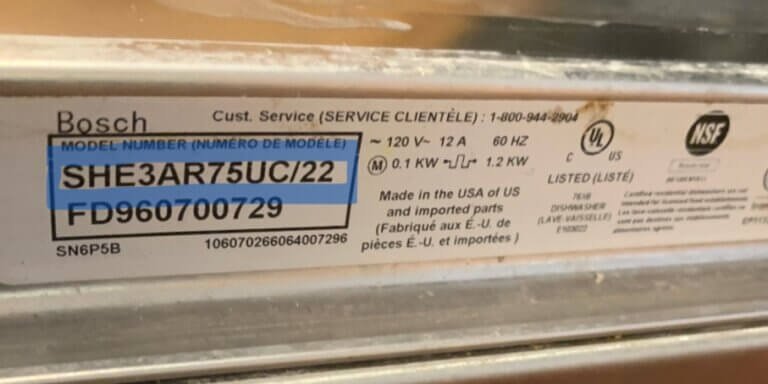

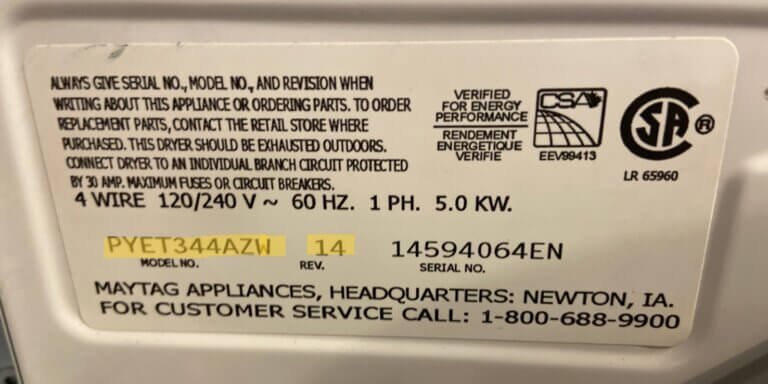

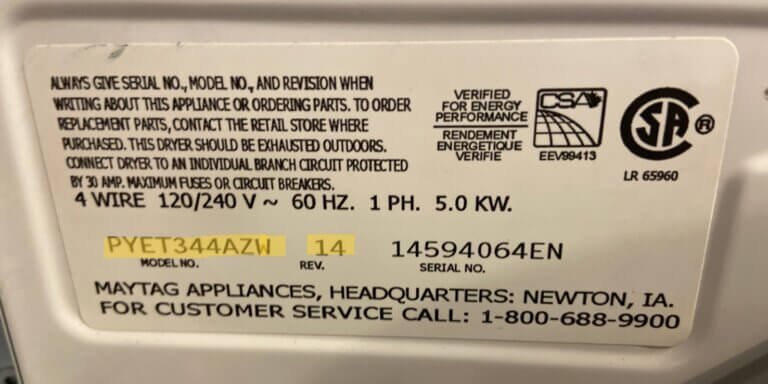

Sample 2:

Samsung appliances are tricky. To get the correct Model and Serial. You need to combine all the information shown in this photo. If a technician or customer orders a replacement part to fix the appliance. You need to make sure that this information must be provided to the parts supplier. This will make sure you will get the correct version of parts and 100% compatible with the existing appliance being repaired or serviced.

Max Currect Consumtion : 3.5A

Refrigerant : R134A

Dimentions: 908(W) x 897 (D) x 1771 (H ) in mm

High Side Pressure 400 PSI Ga

Low Side Pressure 140 PSI Ga

Looking at this photo clearly it has many helpful information.

All samples above are just helpful tips in making sure you are aware of such variation and information that can be used when identifying the appliance. So when time comes that the unit needs repair or serviced, it will be easy to do part lookup and making sure to order correct versions of control electronic boards and many more.

Types of Appliance We Repair and Common Issues

10 Common Washer Problem Our Team Perform Washer Repair Service

1. Clothes not getting washed properly: This could be caused by an incorrect temperature setting, a blocked filter, or insufficient detergent.

2. Machine is leaking water: Check all hoses and connections leading to the machine for any signs of wear and tear or damage.

3. Washing machine is making loud noises during cycle: This could be an issue with the spinning mechanism or a loose component.

4. Washing machine has stopped mid-cycle: Check to make sure that there is no power outage in your area, then reset the washing machine’s timer and try again.

5. Clothes coming out of the wash too wet: Your water temperature may be set too low or your spin cycle may not be working properly.

6. Washing machine is vibrating: This could indicate a problem with the shock absorbers, bearings, or motor mounts.

7. Washing machine won’t start: Check to make sure that the power is on and that there’s no error message displayed.

8. Washing machine overflows: This could be caused by a clogged drain hose or pump, or a malfunctioning water inlet valve.

9. Clothes not getting dried properly: Check to make sure that the vent is not blocked and that the lint filter is clean and working properly.

10. Washing machine won’t agitate: This could indicate a problem with the drive belt, motor, or transmission.

10 Common issues our team performs Dryer Repair.

1. No airflow through the dryer vent: check for lint buildup in the vent and clean it out.

2. Dryer is not heating up: check to make sure that the thermostat is set correctly and replace it if necessary.

3. Dryer has no power: check to see if there’s a tripped circuit breaker or blown fuse, or test the outlet with a voltage meter or appliance tester.

4. Dryer won’t start: verify that the door is closed properly, that it’s plugged in, and that all of the settings are correct.

5. Drum doesn’t turn: inspect the drive belt for signs of wear or deterioration and replace it if necessary.

6. Dryer is too hot: check the temperature settings and adjust them accordingly.

7. Excessive noise or vibration: tighten any loose screws, nuts, bolts, and other fasteners to reduce vibration.

8. Clothes not drying properly: check the lint filter for blockages and clean out if necessary; also make sure that the exhaust vent is open and unobstructed.

9. Unusual smells coming from the dryer: ensure that all fabric softener sheets are removed from the laundry after each use to prevent build-up on heating elements.

10. Dryer won’t stop running: check the cycling thermostat for proper operation by testing with a multi-meter or thermometer; replace if necessary.

10 Common issues our team performs Cooktop Repair.

1. Not heating properly: Check the burner ports, electrodes, and igniter for any blockages or clogs that could be preventing proper heat distribution from taking place.

2. One or more burners not lighting: Inspect the wiring to ensure it is connected properly and check to see if any flame sensor issues can cause a burner not to light.

3. Uneven heat distribution: Make sure all burner caps are centered and evenly spaced over each port and clean out any debris at their bases that may be affecting this issue.

4. Flame burning too high/low: If your flame is too low, you may need to adjust the air shutter located inside the appliance; if it is too high, check the pressure regulator and make sure it is in proper working condition.

5. Powers on but no heat: Check the burner wiring or ports for any clogs that may be preventing them from allowing a spark to ignite the fuel properly.

6. No power at all: If there’s no power going to your cooktop appliance, you should inspect the wiring, circuit breaker, and electrical outlet for any problems that may be causing this issue.

7. Burners won’t stay lit: This could indicate an issue with the flame sensor which needs replacing to ensure the ignition of each burner is consistent and reliable.

8. Too much smoke coming out of burners: Check for any clogs or debris that may be blocking the ports and make sure the burners are not being overfilled with fuel.

9. Not reaching the desired temperature: Adjust the air shutter to allow more air into the appliance if necessary, as this can affect how quickly it reaches a set temperature.

10. Unpleasant odors coming out of burner vents: Make sure your cooktop is cleaned and maintained regularly to prevent any buildup which could be causing an unpleasant smell.

10 Common issues our team performs Dishwasher Repair.

1. Faulty door latch: Check the inside of the door and make sure all connections are in place and secure.

2. Leaking water: Check for loose seals or cracks around the dishwasher that could be allowing water to escape.

3. Noisy operation: Listen closely to identify any unusual sounds coming from the appliance, such as grinding, scraping, or whining noises.

4. Not cleaning dishes properly: Clean out any debris that has accumulated on the filters or spray arms and replace them if necessary.

5. Not draining correctly: Ensure the drain hose is not kinked or clogged with food particles or other debris that could prevent proper drainage.

6. Unusual odors: Empty any food particles that have accumulated in the bottom of the appliance and run a cycle with a cup of vinegar.

7. Not filling with water: Check to make sure there is the adequate water pressure and that all relevant hoses are connected properly.

8. Poor drying performance: Make sure the appliance’s heating element is functioning properly and replace if necessary.

9. Lack of proper maintenance: Clean out filters or replace them when needed, check for signs of wear on hoses, and inspect seals regularly for signs of deterioration.

10. Detergent buildup or oversudsing: Make sure you are using the recommended amount of detergent for each load and rinse away any residue before reloading.

10 Common issues Our team perform Microwave Repair.

1. Faulty door switch: the door switch may be broken and needs to be replaced.

2. Bad fuses or circuit breakers: check for blown fuses or tripped circuit breakers and replace them if necessary.

3. Poor power supply: make sure the microwave is plugged into a working outlet with sufficient power to operate it correctly.

4. Weak magnetron tube: if the magnetron tube has failed, you may need to replace it.

5. Incorrect timer settings: confirm that the timer setting is set correctly according to the manufacturer’s instructions.

6. Excessive arcing: clean any food residue off of the interior surfaces of your microwave before operating it to reduce arcing.

7. Faulty temperature controls: check for proper operation of the temperature control and replace it if necessary.

8. Broken light bulb: inspect the lighting element in your microwave and replace any burnt-out bulbs.

9. Electromagnetic interference: move other electrical devices away from the microwave, or switch them off, when operating it to avoid interference.

10. Poor ventilation: ensure that the vents are clear and not blocked by other items on your countertop to ensure proper air circulation around your microwave appliance.

10 Common issues our team performs Stove Repair.

1. Faulty igniter

2. Clogged burner orifice

3. Poor gas flow

4. Broken heating element

5. Defective thermostat

6. Loose or broken wiring

7. Accumulated grease and debris in the oven cavity

8. Damaged door gasket seal

9. Faulty temperature regulator dials

10. Malfunctioning control board/display panel components.

10 Common issues our team performs Oven Repair.

1. Cleaning and maintaining the oven’s interior.

2. Make sure that the door is properly sealed when closed.

3. Checking for gas leaks in gas ovens.

4. Replacing malfunctioning heating elements or thermostats.

5. Troubleshooting preheating problems and ensuring the correct temperature settings are used for baking tasks.

6. Calibrating the appliance’s internal clock to ensure accurate timing functions during cooking operations.

7. Inspecting wiring connections and replacing frayed cords when necessary.

8 . Testing igniters, valves, switches, and other electronic components as needed to diagnose performance issues with electric ranges.

9 . Monitoring broiler performance and troubleshooting problems with malfunctioning gas or electric broilers.

10. Inspecting the condition of oven racks, cleaning them regularly, and replacing damaged or worn parts.

This is a good starting point for addressing common oven appliance problems and ensuring that your oven operates safely and efficiently. Remember to always use the oven according to manufacturer instructions and have a professional appliance repair expert conduct any necessary repairs. Taking this approach can help you avoid more serious issues and costly repairs down the line.

10 Common issues to our team performs Refrigerator Repair.

1. Dirty Condenser Coils: The condenser coils are located behind or beneath the refrigerator and should be cleaned every 6-12 months to prevent the motor from overworking.

2. Blocked Air Vents: If air vents become blocked with food, dust, dirt, etc., the cooling system can’t work effectively and will cause your refrigerator to not cool properly.

3. Thermostat Settings: Check that the thermostat is set correctly as incorrect settings can interfere with proper cooling.

4. Overstuffed Freezer Compartment: Too much food stored in the freezer can limit airflow, reducing efficiency and causing temperatures in both compartments to go up.

5. Door Seals Worn Out: Check the door seals for signs of wear and tear. If the seals are warped or cracked, cold air can escape and cause the refrigerator to not stay cool.

6. Defrost Drains Blocked: The drain in your freezer should be clear at all times to prevent ice from building up and blocking the airflow.

7. Motor Malfunctioning: An internal motor problem could be why your appliance is not cooling properly. Get it checked by a qualified technician if you suspect this may be an issue.

8. Fan Not Working Properly: Some refrigerators have fans that help circulate air inside them; check these components if you are experiencing cooling issues with yours.

9. Ice Build-Up: If you notice ice building up in your freezer, this could be blocking airflow and needs to be cleared away.

10. Compressor Issues: A broken compressor can cause your refrigerator to not cool properly and will need to be replaced by a qualified technician.

10 Common issues our team performs Freezer Repair.

1. Check the temperature setting – Make sure the temperature has not been accidentally adjusted too high or low.

2. Clean the condenser coils – Remove any dust and/or dirt that have accumulated on the exterior of the condenser coils by wiping them down with a damp cloth.

3. Vacuum out the interior fan – Ensure that any obstructions in the freezer’s interior fan are removed, as this can cause inefficient cooling and problems with airflow throughout the appliance.

4. Inspect door seals – Look for signs of damage or wear-and-tear to determine if your refrigerator door is properly sealed when shut.

5. Verify correct operation of defrost timer – If your freezer isn’t defrosting properly, it may be due to a faulty defrost timer.

6. Check the evaporator fan motor – A malfunctioning evaporator fan motor can lead to insufficient cold air circulation and cooling issues in your freezer.

7. Inspect the door gasket – Make sure the seal around your refrigerator’s door is intact, as a damaged gasket can cause warm air to enter and affect cooling inside the appliance.

8. Clean off condenser coils if frost accumulates – If frost builds up on the condenser coils, heat will not be properly expelled from your freezer and its temperature will rise too high.

9. Check the interior temperature sensor – If this component is out of order, it can cause incorrect temperature readings.

10. Drain and clean the interior drain pan – If water or dirt accumulates in this pan, it can cause a malfunction and cooling problems with your freezer.

10 Common issues our team performs Range Hood Repair.

1. Filter clogged with grease or dirt buildup: Clean the filter regularly to prevent a buildup of dirt and grease.

2. Fan not running at full speed: Check for any obstructions blocking the fan blades and ensure the fan is connected properly to its power source.

3. Exhaust vent blocked: Inspect the entire exhaust system, including both inside and outside, to make sure nothing is blocking the airflow.

4. Lights not working: Check all connections to ensure they are secured properly and replace lightbulbs if necessary.

5. Noise coming from the range hood while in use: Make sure the fan is balanced and check motor bearings for wear or damage that may be causing excess noise when operating.

6. Grease buildup on walls or ceiling near the stove: Clean off the grease with a degreaser and ensure proper ventilation when cooking.

7. Ductwork not properly connected to range hood: Make sure all sections of ductwork are securely attached and sealed with caulking or foil tape where necessary.

8. Fan motor running but fan blades not moving: Check for any obstructions blocking the blades or that could be causing an imbalance in the system, potentially making it impossible for them to move.

9. Loose screws within the range hood unit: Tighten all screws and bolts to ensure everything is properly secured in place and that no parts are coming loose while operating.

10. Vent cover not opening/closing correctly: Inspect the vent cover and replace any broken or damaged components as necessary. Make sure the hinges are properly lubricated and that the vent is securely attached to the range hood unit.

10 Common issues our team performs Vent Hood Repair.

1. Clogged Filters: Vent hood filters become clogged over time and need to be replaced or washed.

2. Fan Not Working Properly: The fan may not turn on, turn off, or be blowing at a reduced speed due to an issue with the motor.

3. Rust in Ductwork: Due to moisture buildup, rust can form in the ductwork and cause inefficiency of air flow.

4. Excessive Grease Buildup: Grease buildup can accumulate on fans and vents over time due to cooking residue, so these should be cleaned regularly for optimal efficiency.

5. Electrical Connection Issues: There may be issues with the electrical connection between the vent hood and the power source.

6. Damaged Motors: The motor in a vent hood can become damaged due to age, electrical issues, or lack of proper maintenance.

7. Vent Hood Noise: Vent hood noise may be caused by worn bearings in the fan or other components that need to be replaced or maintained.

8. Leaks in Ducts: Moisture buildup and rust can cause leaks in ducts which must be fixed with professional help from a service technician or HVAC contractor.

9. Lights Not Working Properly: Poor wiring connections or burned out bulbs can lead to lights not working properly on a vent hood appliance problem.

10. Excessive Vibration: Excessive vibration can be caused by a worn motor or other components that need to be replaced.

10 Common issues our Appliance Repair Team performs Ice Maker Repair.

1. Poor water flow/pressure to the ice maker.

2. Clogged water line to the ice maker.

3. Over- or underfilled ice trays due to improper adjustment of the thermostat control.

4. Low freezer temperature which affects the production rate and size of cubes formed.

5. Malfunctioning shutoff arm that fails to stop the icemaking cycle when the tray is full of cubes.

6. Broken motor drive coupling or another part that allows the unit’s agitator to rotate properly and deposit cubes into the tray below it.

7. Leaks from seals, gaskets, valves, or hoses in the system causing water wastage or overflowing trays.

8. Clogged drainage tube, leading to water pooling up around the ice maker or in the tray itself.

9. Accumulation of frost and ice inside the unit due to insufficient defrost cycles.

10. Malfunctioning control board causing issues with operating settings, timers, temperature levels, and more.