A washing machine that won't spin is a common problem that leaves homeowners with a drum full of soaking wet clothes and a disrupted laundry routine. This issue indicates a mechanical or electrical fault is preventing the washer from completing its cycle. As certified technicians serving Edmonton, Calgary, and Red Deer, we understand the urgency and have the expertise to provide a reliable diagnosis and repair. This guide explains the causes, safe troubleshooting steps, and repair costs to help you make an informed decision.

What the Problem Means

When a washing machine won't spin, it means a specific part of the cycle has failed, preventing the drum from rotating at high speed to extract water from your laundry. This is often a safety feature triggered by an underlying issue, such as an unbalanced load or a component failure. Understanding the common symptoms is the first step in diagnosing the root cause.

Common symptoms homeowners notice include:

- Dripping Wet Clothes: The most obvious sign is laundry that remains saturated after the cycle should have completed.

- Abnormal Noises: Instead of the usual whirring, you may hear humming, clicking, or grinding as the motor attempts but fails to spin the drum.

- Stalled Cycle: The washer successfully fills, agitates, and drains, but then stops and never initiates the final high-speed spin.

- Error Codes: Many modern washers will display an error code on the control panel, pointing directly to the source of the malfunction.

Knowing the different types of washing machines in Canada can help you better understand your specific appliance.

Common Causes of a Washer Spin Failure

To help Alberta homeowners understand what might be happening inside their appliance, we've created a table outlining the most frequent causes of a spin cycle failure. Each cause includes a description of the issue, the difficulty level for a DIY repair, and the potential safety risks involved.

| Cause | Description | Difficulty | Risk |

|---|---|---|---|

| Load Imbalance | The most frequent cause. Heavy items like bedding or towels clump on one side, triggering a safety sensor that stops the spin to prevent damage. | Low | Low |

| Lid/Door Switch | This safety switch confirms the lid or door is securely locked before allowing the spin cycle to start. A failed switch will prevent the machine from spinning. | Medium | Medium (Risk of electrical shock if the appliance is not unplugged.) |

| Drainage Blockage | If the washer cannot fully drain, a pressure switch will prevent the high-speed spin from starting to avoid water damage and flooding. | Low | Low (Potential for water spillage during cleaning.) |

| Drive Belt | A rubber belt connecting the motor to the drum. It can stretch, fray, or snap over time, preventing the drum from turning even if the motor runs. | Medium | Low |

| Motor Coupling | A small plastic or rubber part on direct-drive models that connects the motor to the transmission. It is designed to break to protect them from overload. | Medium | Low |

| Clutch Assembly | Engages the drum for the spin cycle. A worn-out clutch may slip, causing a slow spin, no spin, or loud grinding noises. | High | Medium (Requires complex disassembly of the machine.) |

| Motor Control Board | The washer's "brain" that sends power to the motor. A failure in the board can prevent it from sending the signal to start the spin cycle. | High | High (Risk of severe electrical shock and damaging other components.) |

| Suspension Rods | In top-load washers, these rods absorb vibration. Worn-out rods can cause excessive shaking, triggering the imbalance sensor and stopping the spin cycle. | High | Medium (Requires significant disassembly and proper balancing.) |

Troubleshooting Steps

Before scheduling a service call, there are a few safe and simple checks you can perform to rule out common, easily fixable issues.

SAFETY WARNING: Always unplug your washing machine from the electrical outlet before attempting any inspection or troubleshooting. Never bypass safety features or perform checks while the appliance is powered.

- Check for an Unbalanced Load: This is the most common cause. Open the lid or door and redistribute wet clothes evenly around the drum. Remove any oversized or heavy items that may have caused the imbalance and run a "Drain & Spin" cycle.

- Inspect the Lid or Door Switch: Close the lid or door firmly. You should hear a distinct "click" indicating the switch is engaging. Visually inspect the switch and the corresponding latch for any signs of cracks, debris, or damage.

- Verify the Machine is Level: An unlevel washer can vibrate excessively, triggering the imbalance sensor. Use a level to check if the machine is flat on all sides. Adjust the leveling feet at the bottom of the appliance as needed until it is stable and does not rock.

- Examine the Drain Hose: Pull the washer away from the wall to inspect the drain hose. Ensure it is not kinked, twisted, or clogged. The end of the hose should be securely placed in the standpipe or laundry sink, not sealed, to allow for proper drainage.

- Clean the Drain Pump Filter: On many front-load washers, a small access door at the bottom front of the machine hides the drain pump filter. Place a shallow pan and towel underneath, then carefully unscrew the cap to drain residual water and clear any lint, coins, or debris from the filter.

- Reset the Washer: Unplug the washing machine from the wall, wait for five minutes, and then plug it back in. This can sometimes reset the main control board and clear minor electronic glitches that may have interrupted the cycle.

If these steps do not resolve the issue, the problem is likely an internal component failure that requires professional diagnosis. Stop here and call a certified technician to avoid personal injury or further damage to the appliance.

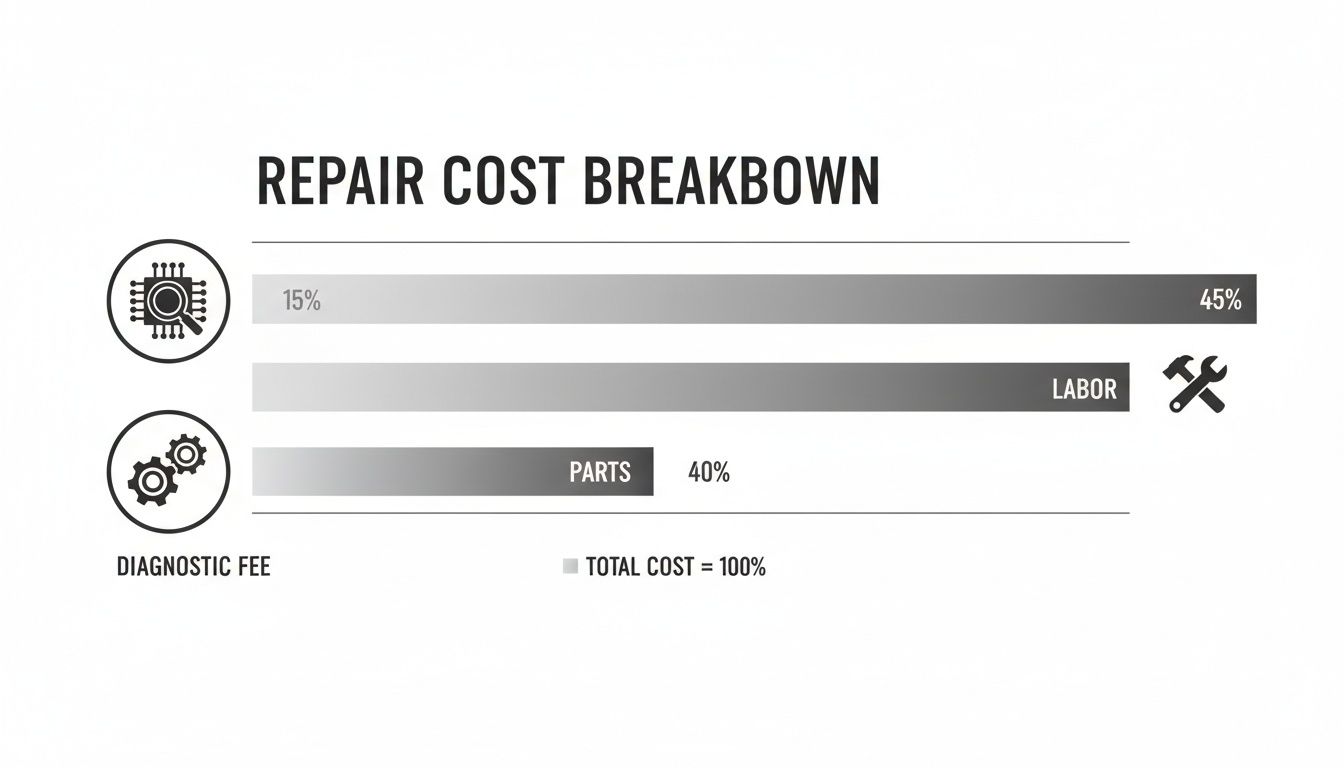

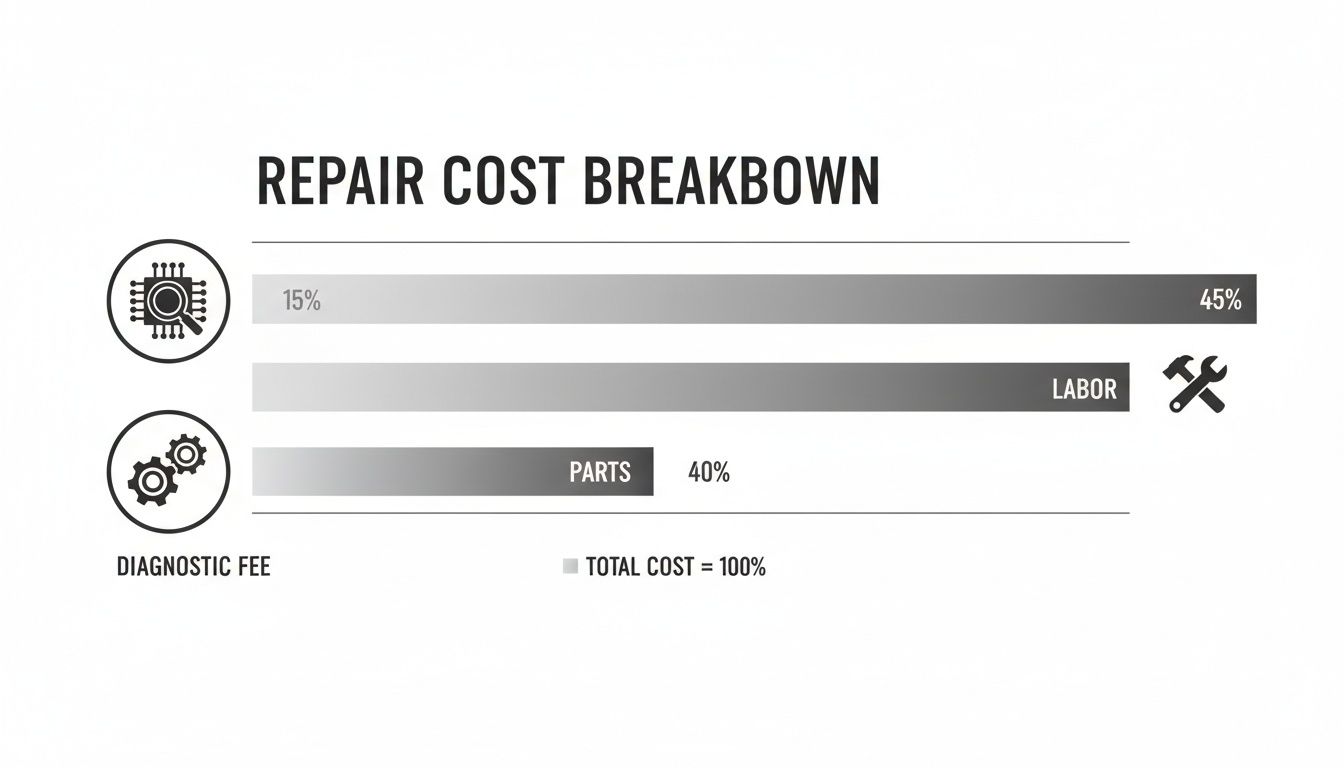

Repair Cost Breakdown

Understanding the potential costs for a professional repair helps Alberta homeowners budget and decide the best course of action.

Please Call to get exact Rates:

Effective starting in 2026, service call fees are no longer waived. The service call fee covers the technician’s travel time, professional appliance diagnosis, and helps support ongoing operational expenses required to deliver reliable, high-quality service. We remain committed to keeping our fees fair, transparent, and aligned with reasonable repairability standards.

Here is a breakdown of typical costs based on current Alberta regional pricing:

- Estimated Service call / diagnostic: $120–$250 (not waived)

- Estimated Parts: $150–$650 (varies by brand and model)

- Estimated Labor: $150–$260 per hour

- Additional travel or mileage charges may apply

GST is not included in these estimates. Prices vary by Edmonton, Calgary, and Red Deer, and all rates are subject to market and economic changes. For a comprehensive overview, see our average appliance repair cost breakdown.

Failure Rate & Repair Cost Chart

Based on our internal data from the previous and current year, we have analyzed the failure rates of common washer components and their associated average repair costs in Alberta. A chart visualizing this data would show gray bars representing last year's figures and light blue bars for the current year. The chart would compare components like the lid switch, drive belt, drain pump, and control board. It would illustrate that while lid switches fail more frequently, their repair cost is relatively low. Conversely, control board failures are less common but represent one of the highest repair costs due to expensive parts and intensive labor. This data consistently shows that parts and labor constitute the majority of any repair bill.

Repair vs Replace

Deciding whether to repair or replace your washing machine is a significant financial decision. We recommend using the 50% Rule as a practical guideline: if the estimated repair cost exceeds 50% of the price of a comparable new washer, replacement is typically the more economical choice.

Consider the appliance's age and expected lifespan. Most top-load washers last 10–13 years, while front-load models often last 11–14 years. Investing in a major repair for an appliance nearing the end of its service life is often not a sound investment.

Finally, brand differences matter. Premium brands like Miele or Speed Queen are built to last and are often worth repairing even when older. In contrast, a major repair on a budget-friendly model may easily approach its replacement value. For a deeper analysis, review our guide on appliances that are worth repairing vs replacing.

Preventive Maintenance Tips

Proactive maintenance is the most effective way to prevent a spin failure and extend the life of your washing machine.

- Do Not Overload: Overloading puts excessive strain on the motor, suspension, and drive components. Wash heavy items like bedding in smaller loads.

- Keep it Level: Ensure the washer is perfectly level to prevent vibrations that can damage internal parts over time.

- Clean the Drain Pump Filter: Regularly (every 2-3 months) clean the filter on front-load machines to prevent clogs that stop the spin cycle.

- Use the Right Detergent: Use only High-Efficiency (HE) detergent in the correct amount to prevent residue buildup that can affect sensors and mechanical parts.

- Run a Monthly Cleaning Cycle: Use a washing machine cleaner tablet or a hot water cycle with vinegar to remove soap scum and prevent odors.

- Inspect Hoses: Periodically check the fill and drain hoses for cracks, bulges, or leaks and replace them every five years as a rule.

- Wipe Down the Seal: For front-loaders, wipe the rubber door seal dry after each use to prevent mold and mildew growth.

- Leave the Door Ajar: After use, leave the door or lid open to allow the drum to air out and prevent moisture buildup.

- Check Pockets: Empty all pockets before washing to prevent coins, keys, and other foreign objects from damaging the drum or clogging the drain pump.

- Schedule Annual Professional Inspection: An annual check-up by a certified technician can identify and address potential issues before they lead to a major failure.

Following these tips is a simple way to maintain performance, as outlined in our guide on 6 ways to keep your appliances working their best.

Brand-Specific Notes

Our technicians' field experience across Edmonton, Calgary, and Red Deer reveals that different brands have unique weak points related to spin failures.

Amana, Bravos, Cabrio, Crosley, Gibson, Goldstar, IKEA, Inglis, Kelvinator, Kenmore, Magic Chef, Maytag, Roper, Tappan, Whirlpool, White-Westinghouse

- Known Issues: On direct-drive top-loaders, a broken plastic motor coupling is the most common cause. For belt-drive models, a snapped drive belt or worn clutch is typical. On front-loaders, a clogged drain pump filter or faulty door lock assembly are the primary suspects. Some modern Whirlpool washing machine error codes can point directly to the issue.

- Parts Availability: Excellent. Parts are widely available across Alberta.

- Repair Difficulty: Low to Medium. These brands are common and well-understood by technicians.

Alliance Laundry, Huebsch, Speed Queen

- Known Issues: These commercial-grade machines are robust. Failures are rare but typically involve a stretched drive belt or a failed drain pump after years of heavy use.

- Parts Availability: Very Good. As an authorized servicer, we have reliable access.

- Repair Difficulty: Medium. Their heavy-duty construction can make disassembly more challenging.

Asko, Miele

- Known Issues: Failures are often electronic. Common issues include a clogged user-accessible drain filter, worn motor carbon brushes, or a malfunctioning control board relay.

- Parts Availability: Good, though some electronic components may need to be special-ordered.

- Repair Difficulty: High. These machines require specialized tools, diagnostic software, and expert knowledge.

Bosch, Gaggenau, Siemens, Thermador

- Known Issues: A blocked drain pump or a faulty door lock assembly are the most frequent causes. The electronics are sensitive and will halt the spin cycle if a sensor reports an error.

- Parts Availability: Good for common parts like pumps and latches.

- Repair Difficulty: Medium to High. Diagnosing electronic faults requires specialized equipment.

Beko, Blomberg

- Known Issues: A malfunctioning door lock mechanism or a failure in the motor control board are common points of failure.

- Parts Availability: Moderate. Sourcing parts can occasionally take longer than for North American brands.

- Repair Difficulty: Medium. Their compact design can make them more difficult to service.

Electrolux, Frigidaire, Frigidaire Gallery

- Known Issues: The number one cause is a failed door lock assembly. A clogged drain pump is the second most likely issue. The control board will not allow a spin if the door lock signal is not received.

- Parts Availability: Excellent. Parts are readily available in Alberta.

- Repair Difficulty: Medium. Accessing the door lock requires careful removal of the front panel and door boot seal.

GE, GE Profile, Café, Haier, Hotpoint, Monogram

- Known Issues: On newer models, a faulty door lock or clogged pump filter is common. On older top-load models, a worn-out mode shifter or transmission is a frequent mechanical failure.

- Parts Availability: Excellent. GE has a very strong parts distribution network.

- Repair Difficulty: Low to High. Varies significantly by model, from a simple filter clean to a complete transmission teardown.

Fisher & Paykel, DCS

- Known Issues: Their unique SmartDrive motor design means failures often relate to the rotor position sensor or the motor control module, rather than belts or clutches.

- Parts Availability: Good. We have access to the necessary components.

- Repair Difficulty: High. Requires specific training on Fisher & Paykel's direct-drive technology.

LG, Samsung

- Known Issues: Failures are almost always electronic. Common issues include a faulty door lock switch, a failed rotor position sensor (hall sensor), or worn-out suspension rods causing chronic imbalance errors ("uE" or "uB").

- Parts Availability: Good for common failure parts.

- Repair Difficulty: Medium to High. Accurate diagnosis requires knowledge of their complex electronic systems.

Viking, Dacor, Sub-Zero, Wolf

- Known Issues: On these luxury brands, spin failures are often tied to the main control board or the motor itself, not simple mechanical parts.

- Parts Availability: Limited. Parts are expensive and frequently require special ordering.

- Repair Difficulty: High. These appliances demand a technician with specific experience in high-end brands.

Caloric, Danby, Hisense, Hitachi, Insignia, Liebherr, Panasonic, Sharp, Thor, Toshiba

- Known Issues: For these diverse brands, common issues often trace back to universal components like the lid lock, door switch, or a blocked drain pump. Their imbalance sensors can also be sensitive.

- Parts Availability: Moderate to Good. Varies by brand and model age.

- Repair Difficulty: Medium. While mechanically straightforward, sourcing the correct electronic part can sometimes be challenging.

FAQs

1. Is it safe to fix a washing machine that won't spin myself?

For simple issues like balancing a load or checking a hose, yes. For any repair requiring you to open the machine's cabinet, it is unsafe due to the risk of electrical shock. Always unplug the appliance first. Internal repairs should be left to certified technicians.

2. How much does it cost to fix a washer that won't spin?

The total cost in Alberta typically ranges from $270 to $910, including the service call, parts, and labor. A simple fix like a lid switch is on the lower end, while a control board or motor replacement is on the higher end.

3. What is the most common reason a washer won't spin?

An unbalanced load is the most common reason. The second most common cause is a faulty lid switch or door lock assembly.

4. When should I replace my washer instead of repairing it?

You should consider replacement if the repair cost exceeds 50% of the price of a new, comparable washer, or if your appliance is older than 10-13 years and requires a major repair.

5. Does my warranty cover this type of repair?

Manufacturer warranties typically last for one year and cover defects in materials and workmanship. If your washer is older than a year, the repair will likely not be covered unless you have an extended warranty.

6. Why won't my top-load washer spin, but it agitates?

This classic symptom often points to a worn-out clutch assembly, a broken drive belt, or on older direct-drive models, a failed motor coupling. These parts are essential for the spin cycle but not for agitation.

7. Why is my front-load washer not spinning and the door is locked?

This usually indicates a drainage problem. The machine will not spin or unlock the door if it detects water is still in the drum. The issue is likely a clogged drain pump filter or a blocked drain hose.

8. Can a clogged drain cause a washer not to spin?

Yes. All modern washers use a pressure sensor to detect the water level. If the machine cannot drain properly due to a clog, the sensor will prevent the high-speed spin cycle from starting as a safety precaution.

9. How long should a washing machine last?

The average lifespan of a top-load washing machine is 10-13 years, while front-load washers typically last 11-14 years. Regular maintenance can help extend this lifespan.

10. When is it time to call a professional technician?

If you have performed the basic troubleshooting steps (checking the load balance, hoses, and filter) and the washer still won't spin, it is time to call a professional. Continuing to try and fix it can lead to further damage or injury.

Final Summary

A washing machine that won't spin can be caused by a simple issue like an unbalanced load or a more complex problem like a failed drive motor or control board. While homeowners can safely perform basic troubleshooting, any repair involving the machine's internal components carries a risk of electrical shock and requires professional expertise. The safest and most effective solution is to obtain a professional diagnosis from a certified technician who can accurately identify the fault and perform a lasting repair with the correct parts.

Reviewed by certified appliance technicians at Advance Appliance Ltd serving Alberta homeowners.

Book Your Washer Repair in Edmonton

Don't let a non-spinning washer disrupt your household. For homeowners in Edmonton and surrounding communities, fast and reliable help is available. Our certified technicians can diagnose the problem accurately and get your appliance running again.

Same-day or next-day appointments available. Certified technicians. Warranty on parts and labor.

Call: 587-882-3225

Book Online: https://advanceappliance.ca/scheduler/